Things are progressing very slowly on the cutting table. This table is too short, it’s an old dining table and 29.75″ high. I should be cutting at 36″ high. My old table at The Stitchery was 39.5″. The one table that was the correct height was my embroidery work table and now it is our dining table. And, remember, I’m cutting 5 workshirts from a denim cambric

Ouch, I need a break, lots of them!

Lately it’s almost impossible to cut more than 1 piece before my back is in spasms. I cut, I go sit. Over and over. I don’t remember having this happen before, usually I can push on through, not right now.

Ever had a project become bogged down from surprising circumstances?

Well, the mind is willing, even if the body is not. I decided to make the job even worse by pulling the fine shirtings that have been waiting for years upon the shelves.

I always like to cut as much as possible from the pattern before me, it makes more sense than cutting one garment and searching for another pattern, ’cause I can take for—ever to decide what’s next. It’s bad. And old production habits die hard.

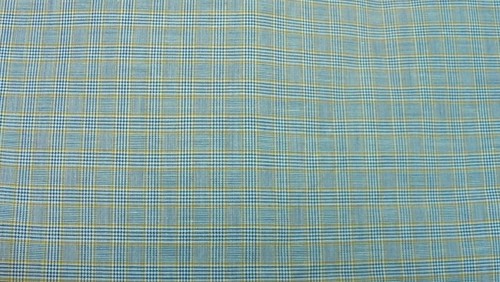

I have these lovely fabrics that have been waiting for shirts for the husband. This new piece just came in from Acorn.com in

I didn’t know the source of the blue stripped fabric, purchased from The Wool House, until I went to Acorn’s website

This top fabric has the lightest hand of all

and while I bought it for him, I may cut it into a shirtdress for me. It suggests “feminine”

This last piece is the most unbelievably silky hand, the finest denim I’ve ever seen. It may be too good for this pattern. Maybe I should wait to cut this when I find or draft the most amazing shirt ever? Yeah, probably.

I bought it from The Wool House in Toronto when I went to meet Els and Lorna in 2011. This is seriously fine cloth and most likely from Italy, since that’s where their fabrics are supposedly sourced.

So, I’m cutting slowly and wondering how to get this table raised when I really don’t have the bricks or vegetable cans to put under the legs. Oh OK, I should go buy the 5″ tall cans and insist that my husband help me get them under the table legs.

A woman’s got to do what a woman’s got to do. Well, if he wants the shirts, right?